How to Make the Perfect Pastorale Fork

Specs for a custom fork

My style of glassblowing isn't terribly common and the way I've evolved it is unique to me. This means that I occasionally need tools that aren't commonly made or I want them made a certain way.

Heating plates of cane or murrine in the glory hole requires a pastoralle fork, but all the ones I've used in the past were compromised in some way until my current fork, which is a hybrid design. I've found solid forks are too heavy unless they're made of thinner stock, but then they're often too weak. Hollow forks can be too lightweight and prone to bending for my work.

Alloy makes a difference too; mild steel spalls, loses strength and rapidly degrades under intense heat. Some forks are poorly balanced by being front-heavy making them especially awkward to handle. Some have tines too close together, or have a box for the tines--both make it difficult to impossible to pick up and balance large plates. Some don't have a perpendicular handle at the far (cold) end which makes it susceptable to flipping if the plate gets the slightest bit tippy. You get the idea.

I got my fork from a friend a decade ago and after many hundreds of heat cycles the metal eventually burned up and I need to rebuild it. The photo shows the burned up tines of the old fork--it's got a giant hole that powdered metal (I think carbon) poured out of when tapped. It's literally toast. I've rebuilt the fork twice and refined my specs each time and it's only gotten better with each rebuild. The latest rebuild was by Spiral Arts and it's better than ever. My design requirements were:

- Super strong but lightweight = hollow tines and handle to save weight and help balance, with solid stainless rod section in between (tine strut and hot side of handle). Stainless of 309 or 310 is supposed to be best for high heat, but Fred convinced me 304 would be fine. I went with .187" wall seamless for a little extra life.

- Reasonably well-balanced with a large plate on it = a longer fork with solid T-handle (perpendicular) for counterweight.

- Heat resistant = stainless steel alloy througout with medium thick walls for tube sections.

- Wide tines = greater stability and flexibility with larger plates

- Shielded against flame = all openings sealed

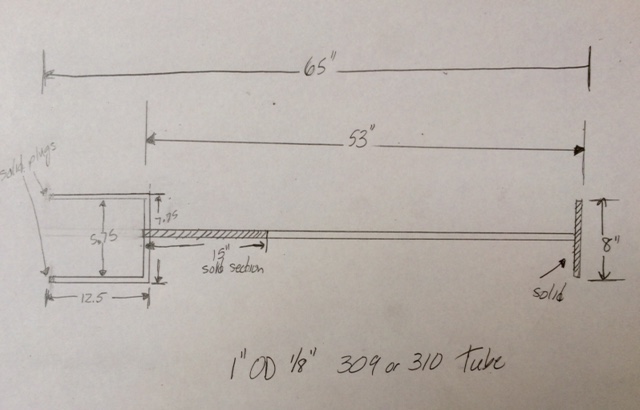

Attached is a photo of the specs I sent to Spiral Arts; from this they custom-built the bottom of my fork. I had a local metalworker TIG it to the handle of my current, burned out fork. I'm back in business without breaking my assistant's back. Note this sketch has accurate measurements, but old specs on steel thickness and alloy.